In addition to production metrics, manufacturing equipment statuses are also displayed. Operators or maintenance workers can quickly see and react if a machine is operational, being resupplied or out of service based on the icons and colors associate to the equipment on the display.

Red Lion Case Study: Blizzard Ski

Contributed by | Red Lion

Blizzard, a leading ski manufacturer based in Austria, was looking for an industrial automation solution to extend manufacturing visibility and control across five machine production stations for wood working, sanding, pressing, assembly and packaging. In addition to utilizing existing hardware, the industrial solution needed to collect Key Performance Indicator (KPI) data and send Andon messages from key production equipment as well as display profitability metrics in the production hall.

Challenges

- Collect data from existing systems

- Display manufacturing metrics

- Minimize production downtime

Solution

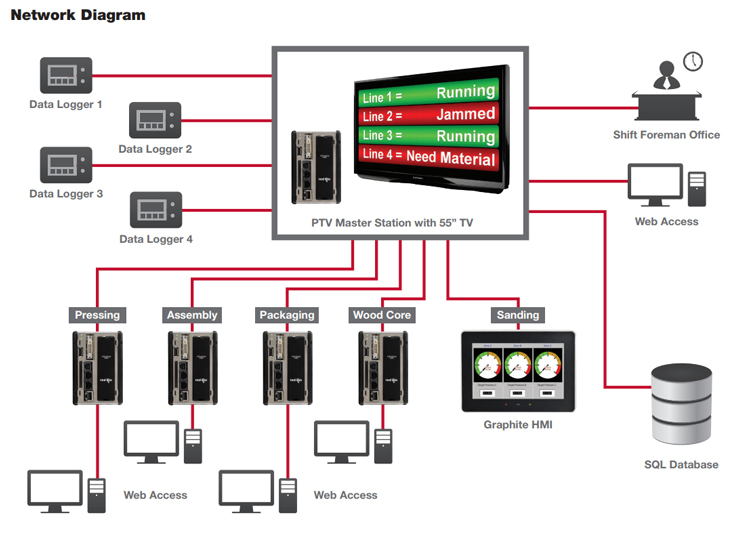

Blizzard worked with Red Lion distributor Reliste, an Austrian provider of control and communication systems, to deploy Red Lion’s ProducTVity Stations and a Graphite® Human Machine Interface (HMI) operator panel alongside its existing hardware, which includes a data logger that utilizes Modbus TCP/IP for device-to-device communication. The combined Red Lion solution enables Blizzard to improve profitability by driving production efficiency without machine changes.

With support for over 300 industrial protocols, multiple communication ports and a display output, the ProducTVity Station is a visual management system that collects real-time data and performance metrics from Blizzard’s manufacturing operations. ProducTVity Stations were installed along with a local PC at Blizzard’s wood core, pressing, assembly and packaging stations to collect KPI data for current piece count, nominal piece count and nominal piece count for the current work period. These metrics are then displayed on a production scoreboard via a television that can be viewed by employees and management. In addition, a rugged Graphite HMI was installed at the Blizzard sanding station to enable easy touchscreen input in a highly dusty environment.

Benefits

The Red Lion solution enables Blizzard to raise production output and minimize equipment downtimes. By adding a visual management scoreboard to the Blizzard production hall, the manufacturing team is now able to see graphical representations of real-time production data. This data includes completed and target piece count metrics from five wood working, sanding, pressing, assembly and packaging machine production stations. Easy at-a-glance visual access to this information allows personnel to proactively monitor and manage each station to meet production goals and better support downstream operations.

In addition to production metrics, manufacturing equipment statuses are also displayed. Operators or maintenance workers can quickly see and react if a machine is operational, being resupplied or out of service based on the icons and colors associate to the equipment on the display. With this form of visual management, Blizzard expects to achieve a greater degree of transparency regarding overall production activity.

Products

About Red Lion

As the global experts in communication, monitoring and control for industrial automation and networking, Red Lion has been delivering innovative solutions for over forty years. Our automation, Ethernet and cellular M2M technology enables companies worldwide to gain real-time data visibility that drives productivity. Product brands include Red Lion, N-Tron and Sixnet. With headquarters in York, Pennsylvania, the company has offices across the Americas, Asia-Pacific and Europe. Red Lion is part of Spectris plc, the productivity-enhancing instrumentation and controls company. For more information, please visit www.redlion.net.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product