Computer-aided engineering software is a revolution in design and project management. With a full buy-in from senior managers, a company adopting such a powerful program strengthens its competitive position.

Computer-aided Engineering: The Future Is Now

Contributed by | Eplan USA

Computer-Aided Engineering (CAE) software is the designer’s best friend, a tool proven to enhance the productivity of the user. It has liberated engineers from the most tedious aspects of their job, shortened project turnaround times and improved the quality and accuracy of their work.

For example, electrical CAE (E-CAE) systems have assumed all functions once performed manually or by using more than one program, like a computer-aided design (CAD) package to create graphical schematics and the table-based Microsoft Excel to create parts lists. Those programs couldn’t share data with each other, which necessitated a great deal of manual (and redundant) data entry, crossreferencing and error-checking. That is a low-value use of an engineer’s time and a complex machine or plant design required an awful lot of it. Today’s advanced electrical CAE programs have automated these and many other non-value-added tasks like wire numbering and device tagging. Engineers are completing assignments that once took days or weeks in a small fraction of the time.

The latest generation of CAE programs has broken decisively from CAD and earlier CAE tools by adding a powerful central database that enables them to provide substantial additional automation. This database can hold a large archive of recurrent content, ready for insertion into a project with a single keystroke. Engineers can convert project documentation into different languages or regional, national and international standards. This makes the database-centric CAE wellsuited for cross-country and cross-border collaborations or for serving a multinational customer base.

With all of their labor- and time-saving features, database-centric CAE programs provide a greater benefit of ownership than older software by making the individual user that much more productive. However, they make an even more compelling business case with their capacity to make every phase of a job, from design through production, more efficient or cost-effective with gains like:

Improved accuracy. With their unprecedented automation, the databasedriven CAE delivers a systematic reduction of errors, error-checking and data redundancy. That means few if any errors survive to the manufacturing stage or beyond, where they are significantly more costly to fix.

Leveraging recurrent content. Storing and reusing data opens the way to standardizing and modularizing product content, accelerating design and manufacturing and enabling large economies of scale in purchasing components.

The benefits of standardization are so great some companies re-design existing models to maximize standard content so design and manufacturing for subsequent orders take less time. Others invest considerable resources creating large content archives as part of their transition to a database-driven CAE. The archive can store frequently used components or complex macros of product assemblies and sub-assemblies, all pre-validated.

Creating efficiencies through transparency. The database can be integrated into a company’s IT architecture, allowing other departments to monitor a project’s progress for more accurate customer quotes, more timely and cost-effective stocking of components and more reliable production and delivery scheduling.

Streamlined interaction with stakeholders. Project files can be exported to customers and reimported with changes to speed up revisions and approvals, and exported to subcontractors to shorten delivery times. Engineers can import component data directly from vendor catalogues.

3D prototyping. Merging data with 3D modeling software enables engineers to create virtual prototypes to prove a design prior to manufacturing. Mechatronic engineering requires smooth connectivity between mechanical engineering and all other engineering disciplines.

Superior machine setups. Automated setups of wire processing and enclosure manufacturing machines turn around orders faster with highly precise results every time.

The efficiency gains begin with the receipt of project specifications and continue forward. EPLAN’s Electric P8 E-CAE, for one, offers a module that can perform an automatic analysis of incoming projects to identify deviations from standards and quality requirements.

When actual project work begins, engineers on these advanced systems can begin at different starting points and need not follow a prescribed order. Facing a rush order, an electrical engineer might assemble component macros or PLC schematics first, compile a parts list to assure the availability of components for an early manufacturing start, then finish the job by numbering devices and wires and generating all documentation.

Most CAE systems are discipline-specific. A select few, like EPLAN, support design software for electrical as well as other engineering disciplines, becoming, in effect, powerful multidisciplinary platforms. Traditionally, engineering disciplines work separately, often with different software tools, passing a project back and forth as content is added or changed. When a process engineer adds a pneumatic-controlled butterfly valve to a design, the fluid engineer must add the fluid drive and the electrical engineer must provide control for it. Working separately, each designer’s intent is self-referencing and may not be well understood by his or her colleagues. Working together, the same engineers form a multidisciplinary team that handles a project concurrently, on the same platform, with greater speed, accuracy and a high degree of assurance their contributions fit well together. Data is shared across all disciplines and as changes are made, the system updates it automatically wherever it appears in or otherwise affects the project.

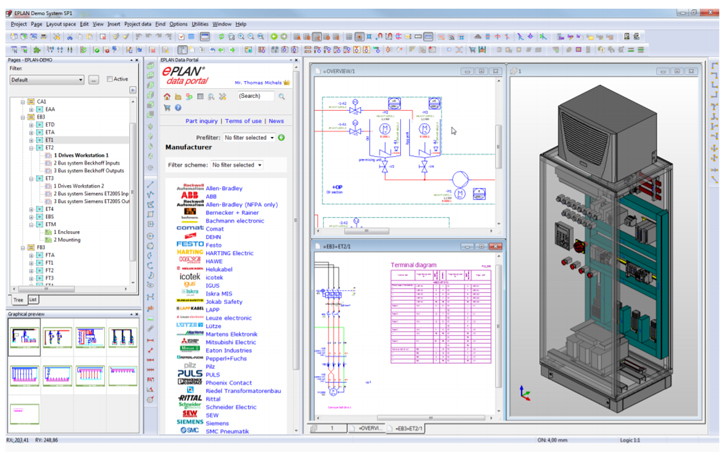

Multi disciplinary user interface of EPLAN including 3D enclosure modeling, P&ID, electrical schematic, all supported with online master data from various component suppliers

Revisions management has been streamlined. Traditionally, the process of obtaining customer revisions and applying them is a delay-prone activity that can disrupt production schedules. Now, with today’s CAE, project documentation can be exported to customers in formats like smart PDFs, and their changes re-imported and incorporated automatically. Once a design is finalized, the CAE automatically generates a complete build package for manufacturing that includes all diagrams, lists and component ID, and if desired, automated setups for NC machining and wire processing.

The maintenance technician in the field is similarly empowered. Product data is typically available in multiple electronic formats, suitable for continuous updating. Project PDFs can be accessed on a laptop or tablet like the iPadTM for quick and mobile troubleshooting and resolution. The CAE viewing tool can be connected to the visualization tool running in the control room. That’s a far cry from arriving at a customer location to find the machine’s printed manual missing, damaged or hopelessly out of date.engineering disciplines work separately, often with different software tools, passing a project back and forth as content is added or changed.

When a process engineer adds a pneumatic-controlled butterfly valve to a design, the fluid engineer must add the fluid drive and the electrical engineer must provide control for it. Working separately, each designer’s intent is self-referencing and may not be well understood by his or her colleagues. Working together, the same engineers form a multidisciplinary team that handles a project concurrently, on the same platform, with greater speed, accuracy and a high degree of assurance their contributions fit well together. Data is shared across all disciplines and as changes are made, the system updates it automatically wherever it appears in or otherwise affects the project.

Revisions management has been streamlined. Traditionally, the process of obtaining customer revisions and applying them is a delay-prone activity that can disrupt production schedules. Now, with today’s CAE, project documentation can be exported to customers in formats like smart PDFs, and their changes re-imported and incorporated automatically. Once a design is finalized, the CAE automatically generates a complete build package for manufacturing that includes all diagrams, lists and component ID, and if desired, automated setups for NC machining and wire processing.

The maintenance technician in the field is similarly empowered. Product data is typically available in multiple electronic formats, suitable for continuous updating. Project PDFs can be accessed on a laptop or tablet like the iPadTM for quick and mobile troubleshooting and resolution. The CAE viewing tool can be connected to the visualization tool running in the control room. That’s a far cry from arriving at a customer location to find the machine’s printed manual missing, damaged or hopelessly out of date.engineering disciplines work separately, often with different software tools, passing a project back and forth as content is added or changed. When a process engineer adds a pneumatic-controlled butterfly valve to a design, the fluid engineer must add the fluid drive and the electrical engineer must provide control for it. Working separately, each designer’s intent is self-referencing and may not be well understood by his or her colleagues. Working together, the same engineers form a multidisciplinary team that handles a project concurrently, on the same platform, with greater speed, accuracy and a high degree of assurance their contributions fit well together.

Data is shared across all disciplines and as changes are made, the system updates it automatically wherever it appears in or otherwise affects the project. Revisions management has been streamlined. Traditionally, the process of obtaining customer revisions and applying them is a delay-prone activity that can disrupt production schedules. Now, with today’s CAE, project documentation can be exported to customers in formats like smart PDFs, and their changes re-imported and incorporated automatically. Once a design is finalized, the CAE automatically generates a complete build package for manufacturing that includes all diagrams, lists and component ID, and if desired, automated setups for NC machining and wire processing. The maintenance technician in the field is similarly empowered. Product data is typically available in multiple electronic formats, suitable for continuous updating. Project PDFs can be accessed on a laptop or tablet like the iPadTM for quick and mobile troubleshooting and resolution. The CAE viewing tool can be connected to the visualization tool running in the control room. That’s a far cry from arriving at a customer location to find the machine’s printed manual missing, damaged or hopelessly out of date.

Selection criteria

Not all CAE systems offer the same power or features. Businesses planning to acquire one should assess the candidates from the following perspectives:

1. Goals. Prioritize your major goals and determine which systems offer the appropriate solution. The greater the economic benefit you desire, then added changes are required through more workflow support and integration. Do you want to establish maximum standardization in automation design? Do you want to improve how engineering workflows are structured? Then you’ll need a CAE platform that supports multidisciplinary design and possesses very large storage capacity. Organizations may not imagine needing so much capacity, but usually make good use of it. For archiving so much content, the CAE should not only feature the ability to create macros and make them scalable, but do so with ease.

2. Integration. The data backbone of the CAE should be robust, able to maintain consistency and avoid redundancy. Organizations can maximize the benefit of ownership if the database is linked to an ERP, PDM or other enterprise software in the IT and PLM landscape. Also, choosing a native CAE avoids a common pitfall. With a non-native CAE that requires host software to run, there is always the risk eventual incompatibility with the host will diminish its effectiveness or force premature replacement. A comprehensive and native CAE possesses all the necessary tools to perform basic and critical functions independently of a host.

3. Support. Most operations require live support yet only some vendors provide it. They generally need an implementation strategy and staff training. A vendor should be able to provide advice for the former and qualified personnel for the latter. Some require special interfaces, custom solutions, or expert troubleshooting, which is why a vendor should have real engineering knowhow on its consulting team. Besides supporting the implementation of the CAE application, engineering consultants should be able to identify opportunities to optimize workflows and processes that boost the productivity of your entire engineering department. When implemented smoothly and professionally, the introduction of a modern CAE system begins contributing almost immediately to the bottom line.

Sink or swim

Computer-aided engineering software is a revolution in design and project management. With a full buy-in from senior managers, a company adopting such a powerful program strengthens its competitive position. By embracing this new technology, it sends a signal to its customers that it plans to remain relevant to their needs. Conversely, organizations not benefiting from this technology risk losing out to competitors making the switch.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product