Cutting-edge polymer science and innovative construction methodologies are being leveraged in composite building construction to solve a broad range of issues associated with water treatment processing and other application challenges.

Innovative Technologies In Composite Building Construction

John Miller | Shelter Works

Engineers today need to keep up with the latest in science and technology so that they can apply those advances to their own projects. Cutting-edge polymer science and innovative construction methodologies are being leveraged in composite building construction to solve a broad range of issues associated with water treatment processing and other application challenges.

This article discusses how advances in materials technology and innovations in field equipment shelters are helping to solve long-standing difficulties for engineers in many different industries.

Field equipment structures need to:

-

Accommodate easy access for both equipment and personnel

-

Handle potentially hazardous conditions and extreme temperature swings

-

Withstand high humidity, hurricane-force winds or Alaskan snow loads

-

Deliver solutions for easily dealing with graffiti and a whole host of other environmental issues

-

Provide a controlled and secure environment for critical equipment.

How do engineers accommodate all this? By leveraging cutting-edge science and innovative construction methodology in composite building construction.

Engineers solve problems by continually asking such questions as “What if...?” and “How can I...?” or “Wouldn’t it be better if we just did this...?” Asking the right questions leads to innovation and technological breakthroughs that can be applied to the real world challenges of industry today.

The Theory Behind Composites

-

A polymer matrix or resin that “holds” the fiberglass reinforcing material

-

Fiberglass that strengthens the structure while still allowing for lightweight construction

-

Gel coats used for both aesthetic and protective purposes

-

Insulating materials to better regulate atmospheric temperatures around the equipment

-

Structural reinforcements that can increase the usability of the shelter

-

Fire retardant materials that can be added to adjust for necessary fire ratings

-

Additional componentry added to the structures to further customize and optimize usage

Each of these elements can be engineered in ways particular to each application by varying the materials themselves, the processes used during the development process and by the final construction.

Composite Fiberglass

Resins

There are two main materials used as the matrix (the substance in which the fiberglass “floats”), depending on the need:

-

Polyester: The most widely used because of its lower cost and high corrosion resistance

-

Vinyl Ester: Used when superior chemical and corrosion resistance, strength and other mechanical properties are needed

Shelter Works’ fiberglass shelters are built using a variety of resin types depending on the application; the most commonly used is what is known as Stypol LSP Unsaturated Polyester Resin.

Resin Additives

In addition to the fiberglass itself, there are many different additives that can alter the properties of the fiberglass itself, such as:

-

Fire Retardants – to improve fire ratings

-

UV Inhibitors – to reduce potential “bloom” caused by exposure to sunlight and moisture

-

Suppressants- to reduce emissions and block evaporation

-

Conductive additives (carbon or metallic fibers that can reduce electro-static charge or make this naturally non-conductive material conductive)

Fiberglass

-

E-glass (most common, originally used in electrical applications)

-

S-glass (stiff or extra-strength glass)

-

A-glass (for alkaline environments)

-

C-glass (corrosion-resistant, stands up to chemical attacks and acids that destroy E-glass)

There are different grades of fiberglass that are used for different environments and in different applications. For example, C-glass is used in soil, whereas woven S- glass can be used with ballistics because it can compete with Kevlar and has high strength to weight ratios.

While some fiberglass products (such as boats or windmill blades) need strength and tensile resistance in a particular direction to offset aggressive forces (like wind sheer or waves), composite fiberglass buildings need to resist forces in every direction.

Because of this, the best methodology for construction of composite construction walls is done with a random orientation of the glass. This is referred to as isotropic strength characteristics. Even within these “grades” of glass, there are differences in the types of glass one can get. Shelter Works chooses a higher-quality E-CR glass that has greater strength, lighter weight and higher corrosion resistance.

Gel Coats

Gel Coats

Composite buildings are manufactured using the same composite materials used to produce today’s advanced marine craft, transportation equipment and aircraft. The materials have been formulated and tested for use in the harshest conditions. Buildings that are constructed with fiberglass materials include an outer layer of protective gel coat in any color desired. Gel coats provide three basic benefits:

-

Protective barrier that increases the life of the building by decades.

-

Aesthetic appeal

-

Long-lasting, maintenance-free performance

Shelter Works’ gel coats are not painted to the exterior. They are molecularly bonded to the underlying fiberglass, becoming a part of the composite. This eliminates any peeling, cracking or chipping.

The Chemistry of Gel Coats

Gel coats are the same basic resin chemistry found in the structural fiberglass composite itself. Only pigments and fillers are included in the gel coat to provide the desired color and to provide resistance to Ultra Violet deterioration and hydrolysis. The gel coat is sprayed into the molds as the first step in the manufacturing process, and it is many times thicker than paint. Once applied, it begins to chemically transform from a liquid to a solid through a process of cross- link polymerization. When the fiberglass composite is applied in the following step, the cross linking of the polymer chains occurs between the layer of gel coat and the layer of fiberglass composite. In essence, the two layers bond as one layer at the molecular level. The color is now not just a coating adhered to the fiberglass; it is an integral part of the fiberglass. Therefore, it will never flake, peel or need to be repainted. For those who need maintenance-free structures that will be aesthetically pleasing over long periods of time, composite structures provide obvious benefits.

What Makes Gel Coats Different

On wood or steel structures, paint or powder-coating is applied to the surface and provides a protective coating. This coating “sticks” to the surface for a while but over time, it will lose its ability to adhere to the surface and can peel, crack, chip or fade. All paints have inherent issues with adhesion and corrosion, requiring routine maintenance or complete refinishing every 5-10 years.

Some types of metal buildings form heavy duty panels for a self-framing design that is painted after fabrication with either liquid or powder paint. Using this method, a successful finish is highly dependent on metal preparation for proper adhesion and uniform coverage to provide a barrier to corrosion. Also, there is a sweet spot for coverage. Too thin and you may not provide a proper barrier. Too thick and it becomes brittle. This is hard to do consistently. A painted surface is not as reliable as gel coat technology, as it is susceptible to corrosion from atmosphere, dents, scratches etc.

Graffiti

Protection and Aesthetic Appeal

Just because they are engineered specifically to meet the rigid requirements of industrial applications doesn’t mean that they can’t look nice. Composite buildings can be made in literally any color desired. While there are “standard” colors, Shelter Works can custom match any color a client might need. These shelters use Isopthalic UV protecting gel coats that maintain a nice gloss over long periods of time and in many weather situations. These coatings provide a quality finish, with good chemical/water resistance, gloss retention, weatherability, and resiliency, which mean that they can resist damage from impact, chemicals, water and even graffiti.

For city officials charged with maintaining attractive-looking buildings, graffiti is an inevitable nuisance that must be dealt with. Composite buildings provide an easy solution to eliminate the illicit artwork spray-painted onto buildings throughout today’s cities. Because the color is molecularly bonded during the construction process, the colorant will be unaffected by the presence of the paint or the chemicals used to remove the graffiti.

Core Materials

Core Materials

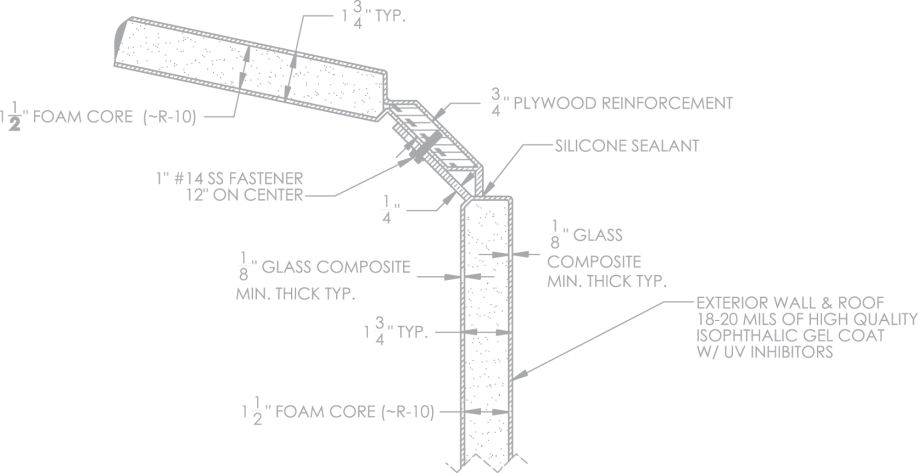

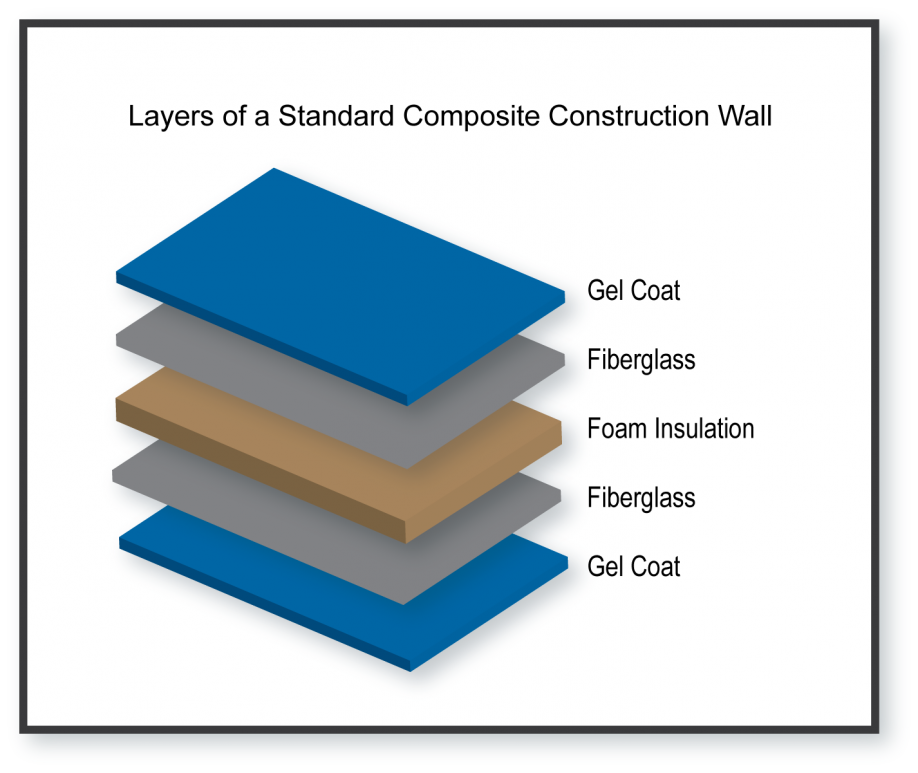

Core materials are commonly used in composite buildings to enhance certain desirable properties of the building. “Sandwich” construction or a modification to sandwich construction can add rigidity without adding tremendous weight, improve insulation and sound attenuation—even provide reinforcements for hanging heavy hardware on the composite structure.

Depending on the needs and application, the following materials can be used:

-

Wood-Balsa, Plywood

-

Foam-Cross-Linked PVC, Linear PVC, Syntactic, Thermoplastic, PMI (Polymrthacrylimide)

-

Honeycomb-paper, aluminum, phenolic resin impregnated fiberglass, polypropylene and aramid fiber phenolic treated paper

Shelter Works Core Materials

-

Foam: Every Shelter Works building includes a foam core, using standard rigid polyiso panel. This foam has been tested for volatile organic compounds (VOC) and formaldehyde emission to ensure it is below the maximum levels allowed and received the Greenguard Environmental Institute highest rating of 4, which means it is highly resistant to mold growth.

-

Shelter Works’ buildings are very energy efficient, with tight joints and high-quality building composite structure. This chart shows the R-Values of the foam alone; the actual R-Value of the shelter could be much higher, depending on the number of openings, vents, fans, etc.

-

Additional Wood Materials: Oftentimes, engineers will specify additional core materials because there is a need to hang equipment or electrical apparatus on the walls. In such cases, walls can be reinforced with OSB, Fir 5- Ply or Marine Grade plywood to enhance performance and use of these composite shelters.

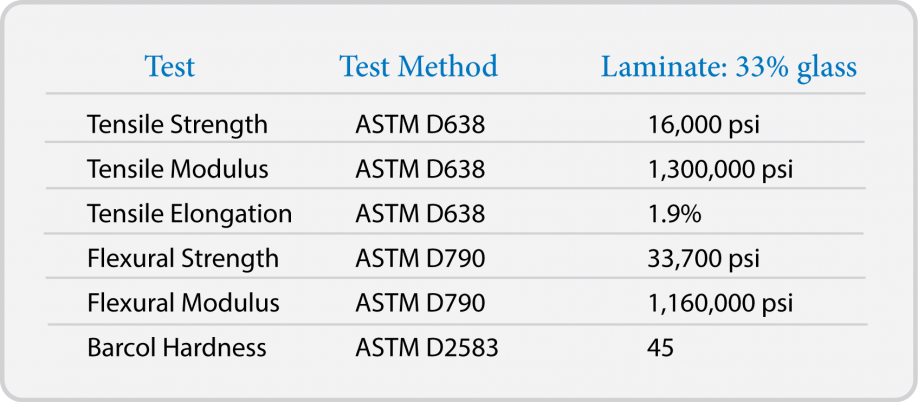

Shelter Works’ Proprietary Composite Lamination Process

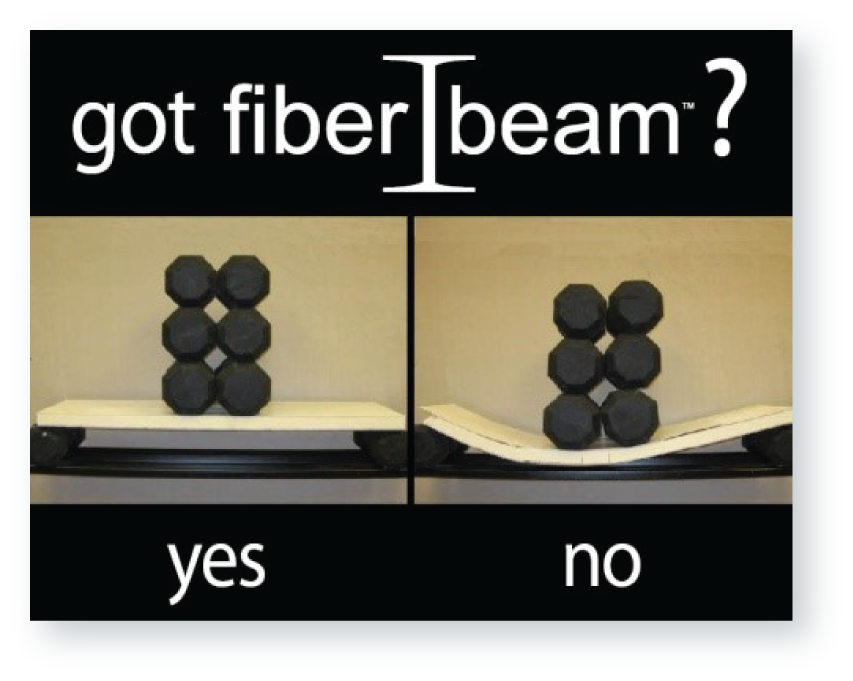

There are several manufacturers of FRP (fiberglass reinforced plastic) buildings that you might think are all roughly similar in construction; rigid sheets of low density foam laminated between two layers of fiberglass, known as a stressed skin sandwich panel. It has been done like this since the early days of FRP and it makes for a nicely insulated structure. Even Shelter Works used this technique early in its history, until it began experiencing some delamination that had to be fixed under warranty. Something had to be done to solve the problem systemically. The team reasoned that no matter how well foam was bonded to FRP the bond is only as good as the molecular strength of the weaker of the two materials - the foam.

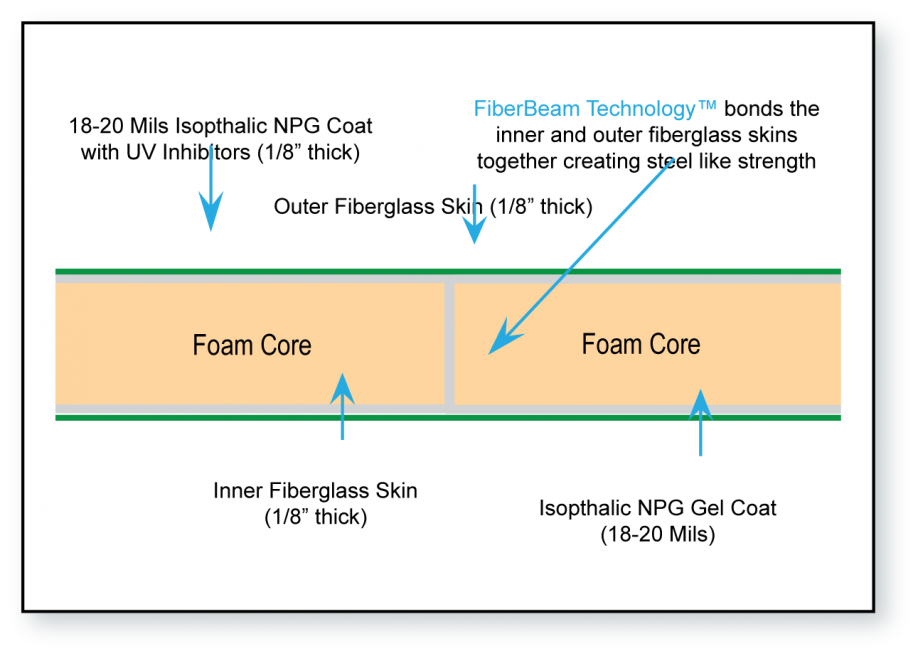

FiberBeam™ Technology is Shelter Works’ innovative, proprietary composite lamination process that bonds inner and outer fiberglass skins with a series of integrated fiberglass I-beams. When a typical FRP panel with foam core is placed under a load the bond between the foam and the FRP is put under stress and can fail. With FiberBeams, the same panel is more rigid and can withstand much higher stresses without failing.

FiberBeams are essentially fiberglass studs, spaced not more than 12” apart that are integrated into all of the walls, roofs and doors, which serve the function of providing a solid, structural connection between the inner and outer fiberglass skins of Shelter Works’ buildings. They are not additional pieces, but rather are integrally formed during the lamination process resulting in a composite panel that can never come apart, or “delamnate”.

Composite fiberglass equipment shelters have the chemical properties that allow for both strength and longevity...But many have experienced the frustration of other manufacturer’s products delaminating or not holding up to the strength requirements they really need. That’s why they have turned to Shelter Works ™because FiberBeam™ Technology, in essence, is long-term structural peace of mind.

Sound Attenuation

IStandard composite construction does a great job of sound attenuation for most applications, with a mini- mum STC rating of 27 decibels. Additionally, optional sound absorbing materials can be added to blunt the noise of machinery even further. One happy Shelter Works client did his own testing as far as how much sound was muffled and sent in his results. What is displayed in this chart is that the noise level inside the structure where the machinery was measured 93 decibels, but standing outside from 5 feet away, the decibel readings dropped off dramatically to 66 decibels. That’s like going from standing by a jet engine to standing beside some-one talking at a normal conversational level.

Longevity

The modern composite industry emerged from the science labs of the 1930’s, was broadly commercialized by the 1950’s and has been going strong ever since. It is not known how long composite structures will last because they have not deteriorated in that time frame. Composite structures from that time period are still in use today, proving the longevity and usefulness of composite construction.

Today’s high-tech composite fiberglass buildings blend state-of-the-art polymer technology and innovative construction techniques with practical processes to create highly attractive, incredibly customizable low maintenance shelters that are used in a wide variety of applications across many different industries.

About Shelter Works

Shelter Works® has been making composite fiberglass buildings for the past twenty years. This St. Louis based company custom-engineers its buildings to meet the particular application. Any size, any color, any electrical or HVAC packages. Built to perform in extreme temperatures, hurricane winds, Alaskan snow loads, coastal climates and corrosive environments. Exclusive FiberBeam™ Technology increases strength and assures uncompromising quality to protect your critical equipment. Rigorous testing done by an accredited independent laboratory.

Shelter Works views its relationships with its clients as long-term partnerships; they rely on Shelter Works to provide long-term solutions that protect for years and years. A 25-year warranty conveys that sense of partnership and gives customers peace of mind. They know they can trust the quality of these products to protect their critical field equipment. If It’s Built By Shelter Works, It’s Built for Life!

Additional information related to Shelter Works is available at http://shelterworks.com/.

About the Author

John Miller has worked in composites for over 10 years and provides his expertise as Director of Sales & Operations for Shelter Works, a field equipment shelter manufacturer that has protected America’s infrastructure for over 20 years.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product