Physical Manufacturing, Outsourcing and the Digital Age of Crisis

While the global covid19 pandemic seems to be fading into the annals of history, the next crisis loomed large before the last one could begin to fade away into obscurity. What do these two most recent crises in the US demonstrate to the manufacturing world?

Evaluating Electronics Contract Manufacturers from Two Perspectives: Supply Chain Management and Engineering

The ideal contract manufacturer is more than a transactional supplier, but a partner that improves the product and process.

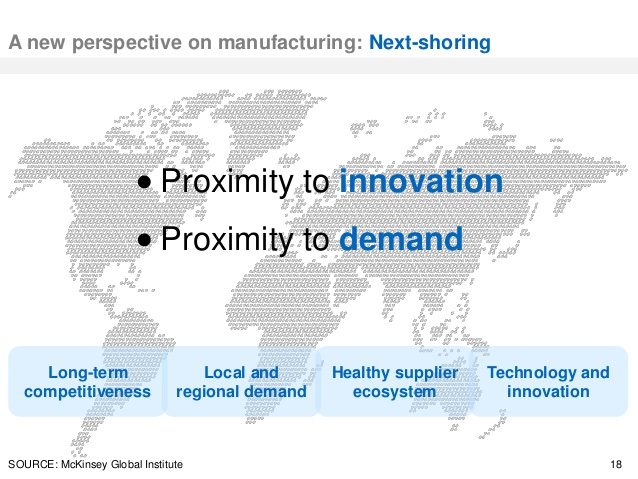

Is Next-Shoring the New Frontier in Manufacturing?

Next shoring involves moving a companys production capacity to where the market for the goods is. For U.S. centered companies, serving American markets, this is the same as reshoring, as reshoring entails moving production capacity back to the U.S. to meet production demands in U.S. markets.

Records 1 to 3 of 3

Featured Product

T.J. Davies' Retention Knobs

Our retention knobs are manufactured above international standards or to machine builder specifications. Retention knobs are manufactured utilizing AMS-6274/AISI-8620 alloy steel drawn in the United States. Threads are single-pointed on our lathes while manufacturing all other retention knob features to ensure high concentricity. Our process ensures that our threads are balanced (lead in/lead out at 180 degrees.) Each retention knob is carburized (hardened) to 58-62HRC, and case depth is .020-.030. Core hardness 40HRC. Each retention knob is coated utilizing a hot black oxide coating to military specifications. Our retention knobs are 100% covered in black oxide to prevent rust. All retention knob surfaces (not just mating surfaces) have a precision finish of 32 RMA micro or better: ISO grade 6N. Each retention knob is magnetic particle tested and tested at 2.5 times the pulling force of the drawbar. Certifications are maintained for each step in the manufacturing process for traceability.