Sharpening Alignment for More Accurate and Faster Machining

AI for End-to-End Quality

Continuous and Exacting Measurements Deliver New Levels of Quality Control

Efficient Warehouse Management: Saving Costs with Rapid Pallet Trackers and Basler ace Cameras

Reducing Manufacturing Cost and Risk with Hybrid AI

Cap Closed! Camera-based Cap Control With Artificial Intelligence

IDS focuses on sustainability in shipping

Three Ways Autonomous Machine Vision (AMV) Benefits Plastic Injection Moulding

Mistakes are sent packing - Autonomous Machine Vision improves accuracy while reducing costs

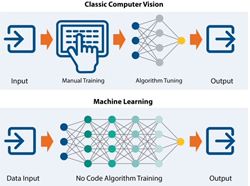

Camera Specs - Not the Frontier in the Era of AI - Autonomous Machine Vision (AMV) Offers a New Approach to Visual QA

Simplifying AI Deployment for Quality Inspection

The Future is Here with Robot Guidance Systems

Machine Vision System Factors

AI-powered Cameras in Factories to Find Defects

Improving Manufacturing Productivity

Records 16 to 30 of 58

First | Previous | Next | Last

Featured Product