Model-based enterprise as a trigger to Digital Transformation

The lack of digital continuity in modern industrial world breaks down silos and leads to considerable communication gaps between different departments. Despite the evident benefits, digitalization still extends over a small range of businesses, while the rest of companies, especially small ones, continue rely on workflows from the analog era. When it comes to industrial and manufacturing design and engineering, here we speak about low paced movement from 2D drawings to 3D models which are definitely more informative, easy-to-use and more adaptable to changes.

Even if the transition from paper-based 2D drawings to digital 3D has been performed, some stakeholders do not have immediate and constant access to up-to-date design and engineering data. Computer-aided design platforms, from where 3D data starts its long journey, are generally complex and expensive systems. Acquiring licenses for all people involved in the workflow can cost businesses a pretty penny.

Even when cheaper alternative is found – a simpler solution with CAD viewing and analyzing capabilities - it often happens that employees use various products for their day-to-day tasks and the synchronization issue appears. Plus, existing CAD viewing solutions can be obsolete and do not respond to performance and multi-format support requirements.

It is worth mentioning, that today not only 3D geometry matters, but auxiliary engineering and manufacturing information which comes with the model is very important for downstream usage. In this case, Model-based definition (MBD) is what the most prospective and competitive companies strive for. This is a new generational approach that allows companies to define, organize, share, store and publish industrial product information in tandem with a 3D model in compliance with regulations and standards. Apart from geometry, the annotated 3D model contains such information as PMI, dimensions, and tolerances, roughness, thicknesses, notes, domain-specific data, auxiliary attributes, etc.

This modern trend has become one of the drivers for accelerated journey to Industry 4.0 and this is one of the pillars for model-based enterprise.

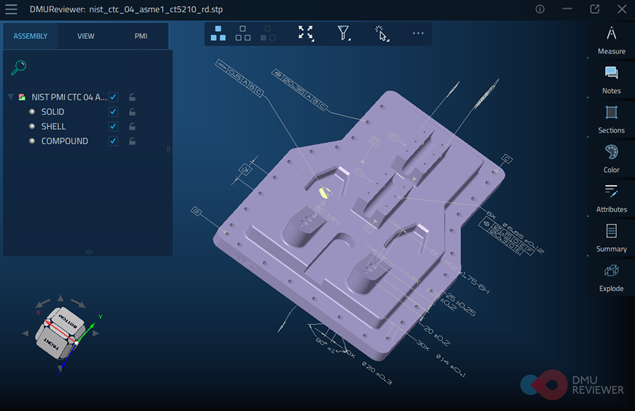

To help businesses keep up with digitalization, Open Cascade embedded MBD approach into one of its software solutions - DMU Reviewer. It is an easy-to-use application which can be operated even by people with little CAD experience. All stakeholders can open CAD files (more than 20 formats are supported, including native ones), view them, make initial design analysis, leave comments and share them with other team members.

This universal CAD viewer bridges technological and communication gaps allowing all stakeholders stay in the context and access the up-to-date design and engineering information throughout the product lifecycle.

DMU Reviewer model-based definition capabilities include:

- Collaboration is made easier due to opportunity to annotate 3D models and exchange comments among people involved.

- PMI can be quickly visualized and analyzed in order to be used in downstream processes

- Geometrical tolerancing is implemented in accordance with ISO 1101:2012 and visualization of GD&T data in a 3D scene in compliance with ISO 16792:2015.

- Detailed analysis of 3D geometry can be performed thanks to advanced feature set (both exterior and inside parts and components can be easily searched and accessed)

.png)

Model-based definition realized in DMU Reviewer

Why do enterprises need MBD solutions?

The solutions supporting MBD processes increase the speed, accuracy, and efficiency of both design and manufacturing enabling smooth and efficient cross department communication. The fact that all stakeholders have immediate access to up-to-date 3D model enriched with associated engineering and manufacturing information provides faster feedback, early defects detection and correction. As a result, better decision-making and faster time-to-market are observed what in general has great impact on business efficiency and competitiveness.

About Open Cascade:

Open Cascade is a software development company which is focused on digital transformation of industries through the use of 3D technologies.

Open Cascade offers a wide range of high-performance proprietary 3D software tools both open-source and commercial. The first ones have been developed, maintained and continuously improved since 2000. Whereas the second ones have been progressively aggregated in Open Cascade Commercial Platform, based on which the company offers creating modern tailor-made industrial solutions that meet even the most sophisticated client’s requirements.

Moreover, Open Cascade expands its portfolio by offering end-user industrial software products and delivering software customization and integration services.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product